Visit www.walter-tools.com

Tel No: + 27 (71) 688 3266

Email: gerald.green@walter-tools.com

Product website

www.walter-tools.com

Walter in brief

The headquarters of Walter AG are situated in Tübingen in the south of Germany. With 33 subsidiaries and a large number of distribution partners, the company’s international representation on all continents is guaranteed: a global service and local technical expertise are very important to us.

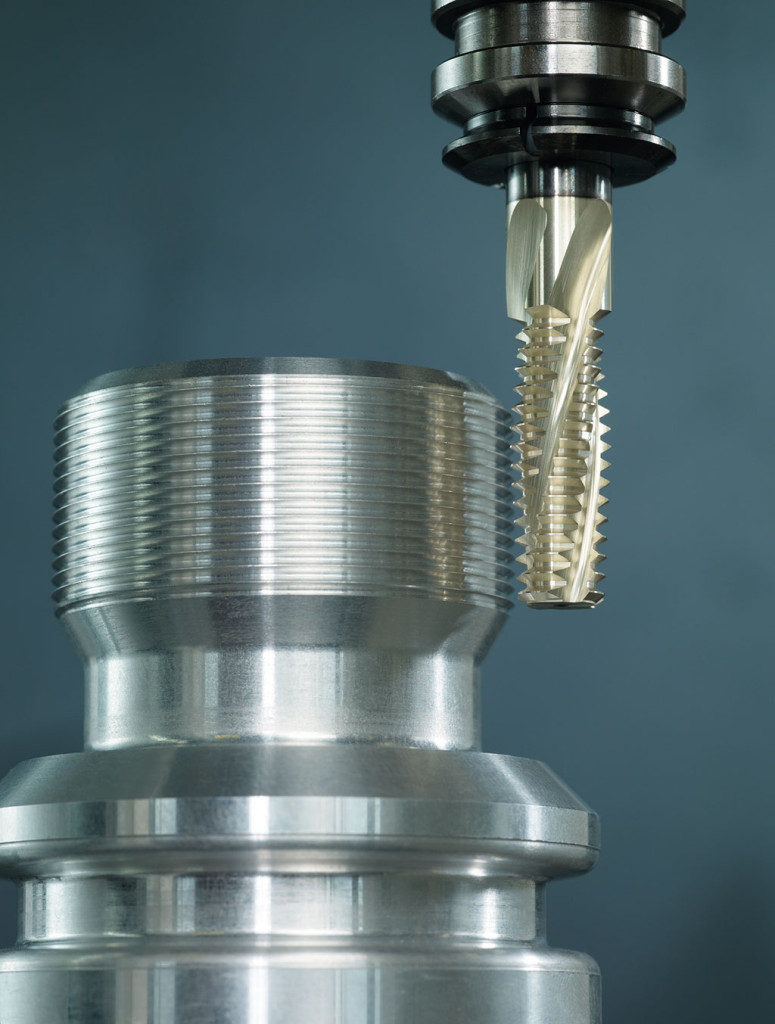

The five competence brands of Walter, Walter Titex, Walter Prototyp, Walter Valenite and Walter Multiply, are united under one company umbrella. With a product range of around 49,000 catalogue tools for milling, drilling, turning and threading, Walter is a complete service provider for the metalworking industry. Specialists working in the relevant competence brands jointly develop integrated processing solutions for machining. Here their comprehensive expertise in the automotive sector, the aerospace industry, energy, rail transport and general mechanical engineering stands them in good stead.

Walter AG develops, manufactures, and markets precision tools for the metal working industry. The company offers a range of milling, drilling, turning, and threading tools for application in automotive and engines, aerospace, energy, railway, and general mechanical engineering industries worldwide. It also provides maintenance solutions, such as reconditioning and recycling; planning solutions; and production and logistics solutions. Walter AG was formerly known as Walter Hartmetall GmbH and changed the name to Walter AG in 2008.. As of February 25, 2002, Walter AG operates as a subsidiary of Sandvik AB.

Founding of the company and continuous development

Richard Walter founded the company in 1919 in Düsseldorf with the name Walter Hartmetall GmbH. The company founder recognised that metal cutting tools were becoming increasingly more important. The foundations for future industrial success were 200 patents that Richard Walter registered over his lifetime. With the acquisition of another small business in 1924, the Walter mining industry was born in Tübingen. In the years that followed, the development of carbide tools continued.

In the 1950s, the product range was expanded to cover tools for machining wood and plastic. In addition, not only carbide tools, but also tool sharpening machines and edgers with inserted tooth cutters were manufactured. Consequently, modular tooling systems were launched on the market and these made it possible to optimally organise tools.

Technologically, Walter’s mechanical engineering division was a world market leader for years. In order to concentrate on their original core competencies – developing and manufacturing tools – Walter Maschinenbau was sold to the Körber Schleifring Group in 2004.

Since the end of the 1980s, the Walter Group has also developed and marketed software for tool data management. It continued this role from 2004 as an independent business unit, trading under the name “TDM Systems GmbH”. In recent years, TDM Systems has been further developed into a system house and a competence centre for tool data management. Around 70 staff from the technology, service and sales departments support more than 1000 customers worldwide. TDM is currently in its fourth product generation. Innovative, customer-orientated solutions are a key to the success of TDM. In addition to the Walter Group, TDM supports other customers in the metal machining industry, including the aerospace industry, the automotive industry, the energy industry and general mechanical and plant engineering.

The way to becoming a global player

Since 1995, the number of subsidiaries or joint ventures abroad has risen dramatically. Subsidiaries in the Czech Republic, Poland, Brazil, Spain, China and Singapore are only a few examples of the company’s continual international development. In 2007 and 2008, wholly owned subsidiaries were founded in Argentina, Malaysia, Russia, Sweden and Japan. Today, Walter AG has a global presence and is active in over 50 markets worldwide – mostly with wholly owned subsidiaries or, in smaller countries, with representatives and co-operation with sales partners. Customers include leading global players as well as medium-sized enterprises in the automotive industry, the aerospace industry, general mechanical engineering, the energy sector and the rail transport industry.

Today, Walter is among the world’s leading metal machining companies, and employs around 4000 staff in 33 subsidiaries throughout the world. The merger of Walter AG in 2007 with two renowned companies in the tool sector – Titex in Frankfurt and Prototyp in Zell am Harmersbach – was an important step on the way to becoming a global player. Titex is known for high-performance drilling and reaming tools made of HSS (E) and solid carbide; Prototyp stands for innovative threading tools and milling cutters made of HSS (E) and solid carbide. This strategic decision allowed Walter to become a complete provider for machining. Walter took a further step in this direction by taking over the US company Valenite in 2010.

Operating in NAFTA markets, the competence brand Walter Valenite offers tools with indexable inserts for turning, drilling and milling, as well as special tools from the high-tech MODCO brand (for example, complex draw bar tools).

Innovative tools are the basis for outstanding machining results. In order to increase the tool’s overall potential, it is just as important to implement these as efficiently as possible. In response to the increasing importance of consulting and services in the tool industry, in September 2010, Walter launched the competence brand “Walter Multiply”. With Walter Multiply, the company offers a tailor-made range of services, which supports customers as they reduce costs and complexity throughout the whole process chain. Walter advises customers throughout the entire production process – from planning through to production and maintenance. As a result, customers will gain far more than what is simply the sum of individual service elements. Multi-step services along the entire process chain will multiply success factors considerably. This means that Walter AG is not only combining the expert knowledge of the five competence brands, but is also offering complete solutions from a single source.

A further acquisition was completed in 2004 with the take-over of the PCD/CBN tool specialist Werner Schmitt PKD-Werkzeug GmbH. The company based in Niefern bei Pforzheim employs around 70 staff. As a result, Walter AG was able to expand its product portfolio with an important range of applications: customer-specific PCD/CBN solutions.

Production facilities at home and abroad

Today, Walter AG owns production facilities around the world in Germany, France, USA, China and Brazil. In Germany, manufacturing takes place at the company headquarters in Tübingen (body manufacture), in Münsingen (indexable inserts), Niefern bei Pforzheim (PCD/CBN tools), as well as Frankfurt (rotating drilling and reaming tools) and Zell (rotating milling cutters, threading tools).

Ground-breaking innovations such as Tiger·tec® Silver, Xtra·tec® and Walter BLAXX

Walter regularly sets standards in the sector. Walter has never failed to impress with its new products that are unique to the market, whether this is with the Quartec® indexable inserts for milling, the “Tough Guys” solid carbide high-speed milling cutters (1999), the Tiger·tec® cutting tool material (2001), the Xtra·tec® tool concept (2003), the Tiger·tec® Silver high- performance cutting material (2009) or the new Walter BLAXX generation of mills (2012).